Proceedings of ASME Turbo Expo 2013 – GT2013-95527

Control valves are one of the key steam turbine components both in terms of operational safety and flexibility. It is hence fundamental to correctly predict the valve characteristics at the various working conditions to accurately estimate machine performance and control logics.

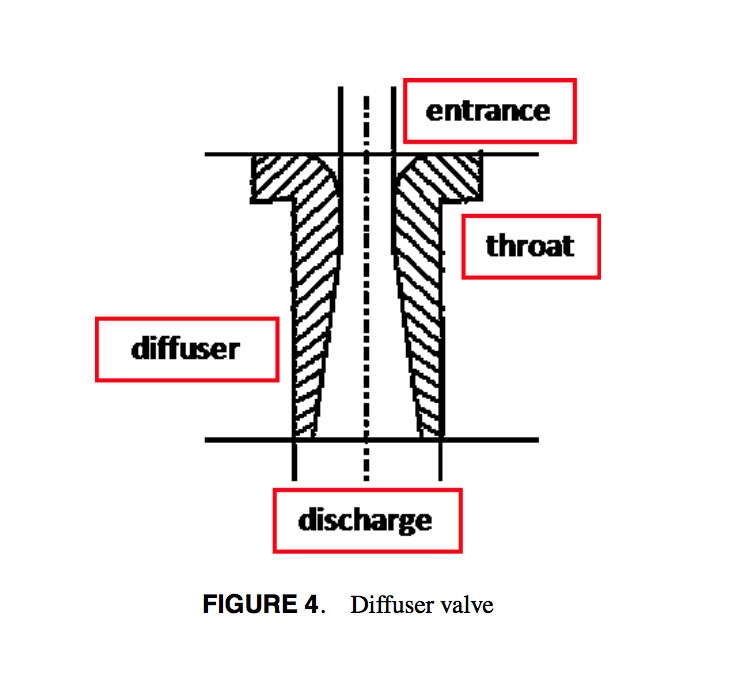

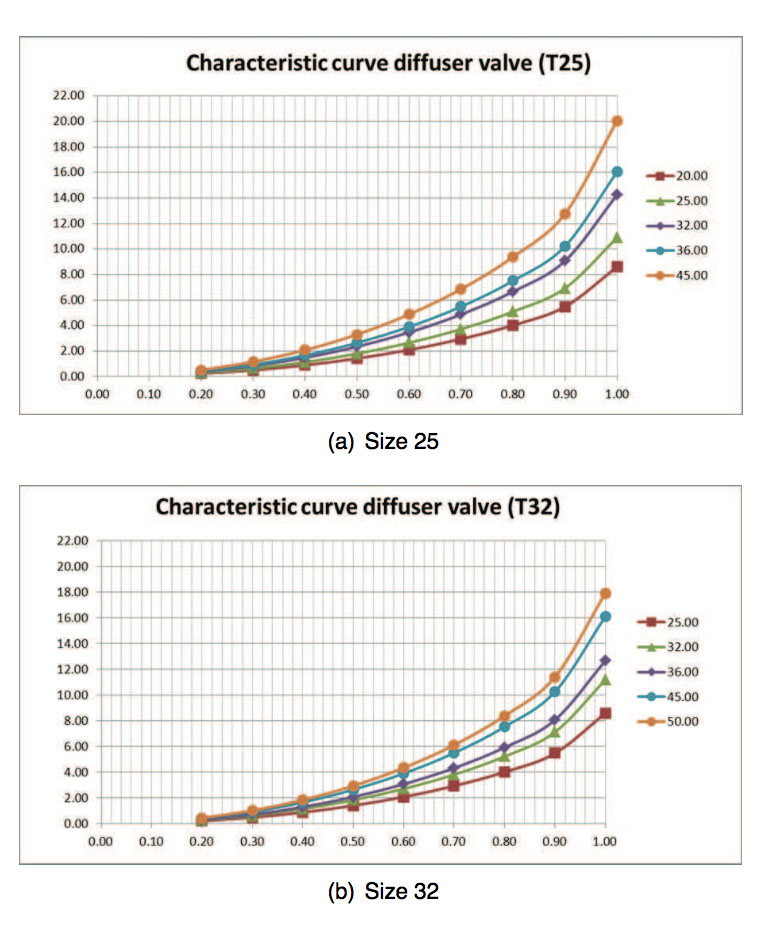

Two types of partition valves typically employed in real industrial steam turbines of different power (from 1MW to 100MW) are analysed. The first type exploits a diffuser like shape to maximize the dynamic pressure recovery before the discharge into the impulse stage. Second type, based on simple tube geometry, increases the allowable flow rate providing higher pressure losses. Geometrical dimensions has been varied to cover a wide range of configurations employed in industrial applications. Exception is made for the diffuser angle and the relative fillet radius which were fixed to guarantee product standardization among the various machine sizes.

The aerodynamic performance of the partition valves were investigated with axisymmetric inflow at various shutter positioning starting from the open valve condition where the influence of the shutter is negligible. Two different solutions of shutter were investigated to allow a characterization of regulation of the steam flow based on the valve lift. The reference conditions for the entire study is 140 bar and 540 °C which are typical working conditions for steam turbines.

Pressure losses were first modelled dividing the partition valve into singular homogeneous parts such as the intake, the straight pipe, the diffuser and the discharge, for which simple correlation were available in literature. Since the experimental data were collected for incompressible flows, the overall characteristic curve was validated using CFD computations reproducing real working conditions. The steady state RANS solver available in the commercial code CFX was used to compute the flow and thermal field exploiting the SST turbulence model. The influence of steam real gas behaviour was explored against perfect gas modelling showing low effects in terms of dimensionless parameters.

The development of the correlation permitted to rapidly cover the selected range of geometries and conditions highlighting a dimensionless parameter able to parametrize losses insensitively to the geometrical scaling.

http://proceedings.asmedigitalcollection.asme.org/proceeding.aspx?articleid=1776459