Journal of Engineering for Gas Turbines and Power 138(7) Nov 2015

Transaction of ASME Turbo Expo 2014 – GT2014-27078

Among the various type of seals used in gas turbine secondary air system to guarantee sufficient confinement of the main gas path, honeycomb seals well perform in terms of enhanced stability and reduced leakage flow. Due to the large amount of honeycomb cells typically employed in real seals, it is generally convenient to treat the sealing effect of the honeycomb pack as an increased distributed friction factor on the plain top surface. That is why this analysis is focused on a simple configuration composed by a honeycomb facing a flat plate. In order to evaluate the sealing performance of such honeycomb packs, an experimental campaign was carried out on a stationary test rig where the effects of shaft rotation are neglected. The test rig was designed to analyse different honeycomb geometries so that a large experimental database could be created to correlate the influence of each investigated parameter. Honeycomb seals were varied in terms of hexagonal cell dimension and depth in a range that well represents actual honeycomb packs employed in industrial compressors. For each geometry five different clearances were tested. This work reports the findings of such experimental campaign whose results were analysed in order to guide actual seals design and effective estimates of shaft loads. Static pressure measurements reveal that the effects of investigated geometrical parameters on friction factor well correlate with a corrected Mach number based on the cell depth.

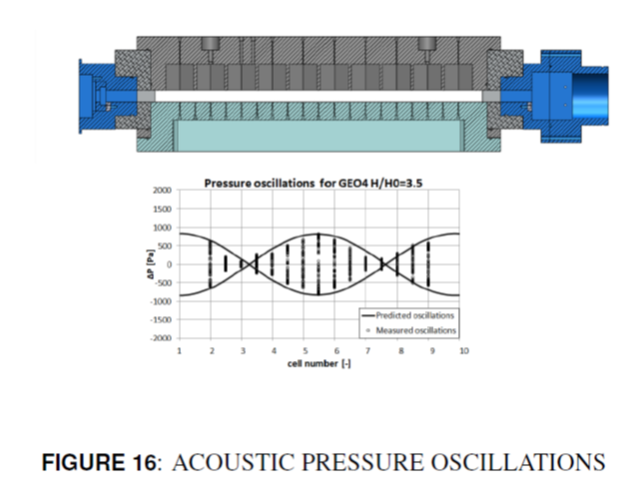

The presence of acoustic effects in the seals was further investigated by means of hot wire anemometry. Acoustic forcing due to flow cavity interaction was found to be characterized by a constant Strouhal number based on cell width. Numerical simulations

helped in the identification of system eigenmodes and eigenfrequencies providing an explanation to the friction factor enhancement triggered at a certain flow speed.

Finally the generated dataset was tested comparing the predicted leakage flow with experimental data of actual seals (with high pressure and high rotational speed) provided by GE Oil & Gas showing a very good agreement.

http://gasturbinespower.asmedigitalcollection.asme.org/article.aspx?articleid=2469758