The Role of Air Conditioning in the Diffusion of Sars-CoV-2 in Indoor Environments: a First Computational Fluid Dynamic Model, based on Investigations performed at the Vatican State Children’s Hospital

We modelled the role of HVAC systems in the diffusion of the contagion through Computational Fluid Dynamics (CFD) simulations of cough at the “Bambino Gesù” Vatican State Children’s Hospital. Both waiting and hospital rooms were modeled as indoor scenarios. A specific Infection-Index (η) parameter was used to estimate the amount of contaminated air inhaled by each person present in the simulated indoor scenarios. The potential role of exhaust air ventilation systems placed above the coughing patient’s mouth was also assessed.

Sciencedirect-download

Autore: lorenzo

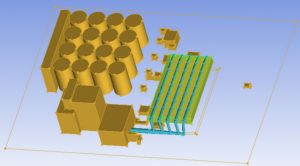

Load independent losses of an aeroengine epicyclic power gear train: numerical investigation

ASME Turbo Expo 2019 – GT2019-91309

The development of Ultra-High Bypass Ratio (up to 20) engines with the aim of improving the propulsive efficiency, introduces new challenges for the transmission system in terms of heat management and power losses, since the amount of power transferred through the gearbox is greatly increased. In this respect the accurate estimate of losses at the various flow regimes realized during a typical aeroengine mission within a Power Gear Box (PGB) is essential for the correct design and operation of the engine itself.

This paper proposes a computational methodology to estimate all fluid-dynamic (load-independent) losses, which become a major source of dissipation at the high rotational speeds typical of aeroengines, developing within an epicyclic PGB. The overall procedure is based on the superposition principle and approaches the three fluid-dynamic losses, namely injection, windage and meshing losses, with different numerical techniques.

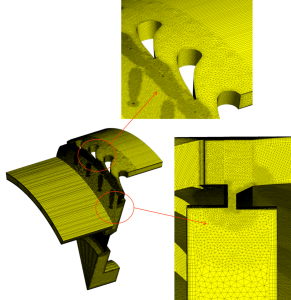

The simulations of windage effects, which consider the actual PGB geometry including the carrier disk, the lubricant spray-bar and the external casing, are based on steady-state computations. In order to introduce such simplification, a scaling procedure that avoids interference of the stationary and rotating interfaces was implemented following the outcomes of a previous analysis.

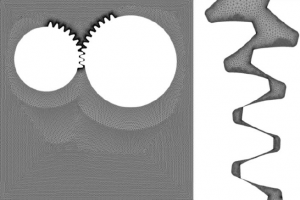

The computation of meshing losses employs a fully unsteady dynamic mesh approach and considers a portion of the meshing gears only. Both the sun-planet and planet-ring meshing were considered showing that the latter introduces a much lower level of losses.

Finally the injection losses are calculated considering the oil jet momentum variation with simplified methods based on 0D modelling.

The proposed procedure, based on the superposition principle and applied to a planetary power gear train, is tested against experimental results described in a previous paper focused on a meshing gear pair.

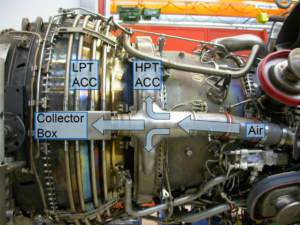

Aero-Thermal Investigation of Convective and Radiative Heat Transfer on Active Clearance Control Manifolds

ASME Turbo Expo 2019 – GT2019-90007

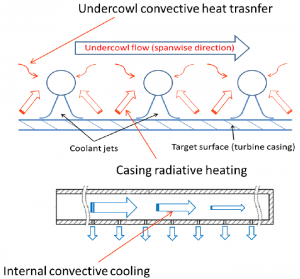

Present paper deals with the characterization of heat transfer on blade tip Active Clearance Control manifolds. Real engine geometries and operating conditions were considered in validated CFD computations to sort out the impacts of both manifold surfaces convective and radiative heat transfer on the aero-thermal performance of the system. Different manifold geometries were accounted for also.

The study sorted out that both the radiation and the convective heat transfer on the manifold surfaces are responsible of performance deteriorations as the impingement heat transfer on the casing is considered. The last evidence is motivated by the fresh fluid heat up along the feeding pipe. Radiative heat transfer from the casing to the manifold is found to be relevant, especially in case of high casing temperature or low undercowl flow rates. As a result of the study, is remarked that ACC manifold radiative and convective heat transfer should be considered for a proper system design.

Windscreen effect on performance and structure, before and after, and comparison with CFD

10th Annual ACC Users Group Conference (2018)

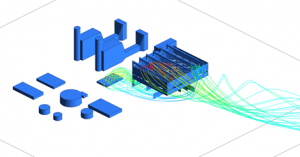

This work describes the application of CFD to predict the wind field and determine the optimal setup for wind screens. This way, it was possible to improve the performance of the Air Cooled Condensers (ACC) and ultimately of the overall power plant.

http://acc-usersgroup.org/presentations/2018-conference/

http://acc-usersgroup.org/wp-content/uploads/2018/11/C.-Bianchini.Windscreen-effect-on-performance-and-structure-before-and-after-and-comparison-with-CFD.pdf

Effect of Rim Seal Configuration on Gas Turbine Cavity Sealing in Both Design and Off-Design Conditions

ASME Turbo Expo 2018 – GT2018-75712

The desired reduction of secondary air consumption of gas turbines is especially challenging when the sealing of stator-rotor cavities is concerned, where it is necessary to guarantee integrity against hot gas ingestion. Sealing and thermal performance of gas turbine stator-rotor cavities are directly dependent on the rim configuration. This paper provides a CFD-based characterization of heavy-duty gas turbine wheel-spaces when dealing with real engine operating conditions and geometries. Focusing on the rim seal configuration, the geometrical arrangement of the ingestion-cavity, the buffer-cavity and the inner cavities were investigated to improve the ingress flow-discouraging behaviour. The study reveals that the most important geometrical parameters affecting the rim sealing effectiveness are those related to the ingestion-cavity. Moreover, an empirical model to predict the stator-rotor cavity sealing performance in off-design conditions was proposed. The model, that consists in an extension of a well-known literature approach, performed well at the analysed operating conditions, confirming to be an excellent tool for the early design phases. Finally, an investigation on the unsteady behaviour of the seal highlights a coupling with an acoustic mode of the cavity, suggesting possible reasons to justify the presence of rotating structures embedded into the cavity flow.

http://proceedings.asmedigitalcollection.asme.org/proceeding.aspx?articleid=2701085

https://www.researchgate.net/publication/327406498_Effect_of_Rim_Seal_Configuration_on_Gas_Turbine_Cavity_Sealing_in_Both_Design_and_Off-Design_Conditions

Effect of Temperature Ratio on Jet Impingement Heat Transfer in Active Clearance Control Systems

J. Turbomach 141(8) 2019 – Transaction of ASME Turbo Expo 2018

Impinging jet arrays are typically used to cool several gas turbine parts. Some examples of such applications can be found in the internal cooling of high-pressure turbine airfoils or in the turbine blade tip clearances control of aero-engines. The effect of the wall-to-jets temperature ratio (TR) on heat transfer is generally neglected by the correlations available in the open literature. In the present contribution, the impact of the temperature ratio on the heat transfer for a real engine active clearance control system is analyzed by means of validated computational fluid dynamics (CFD) computations. At different jets Reynolds number and considering several impingement array arrangements, a wide range of target wall-to-jets temperature ratio is accounted for. Computational results prove that both local and averaged Nusselt numbers reduce with increasing. An in-depth analysis of the numerical data shows that the last mentioned evidence is motivated by both the heat transfer incurring between the spent coolant flow and the fresh jets and the variation of gas properties with temperature through the boundary layer. A scaling procedure, based on the TR power law, was proposed to estimate the Nusselt number at different wall temperature levels necessary to correct available open-literature correlations, typically developed with small temperature differences, for real engine applications.

http://turbomachinery.asmedigitalcollection.asme.org/article.aspx?articleid=2729002

https://www.researchgate.net/publication/331855212_EFFECT_OF_TEMPERATURE_RATIO_ON_JET_IMPINGEMENT_HEAT_TRANSFER_IN_ACTIVE_CLEARANCE_CONTROL_SYSTEMS

CFD analysis for optimal wind screen positioning

9th Annual ACC Users Group Conference (2017)

This work describes the application of CFD to predict the wind field and determine the optimal setup for wind screens. This way, it was possible to improve the performance of the Air Cooled Condensers (ACC) and ultimately of the overall power plant.

http://acc-usersgroup.org/presentations/2017-conference/

http://acc-usersgroup.org/wp-content/uploads/2017/11/2017-Cosimo-Bianchini-CFD-analysis-for-optimal-wind-screen-positioning.pdf

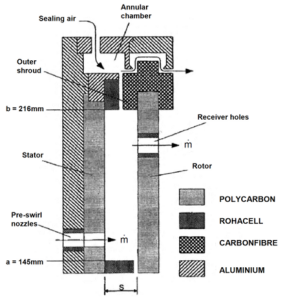

Numerical Characterization of Flow and Heat Transfer in Pre-Swirl Systems

Journal of Engineering for Gas Turbines and Power 140(7) 2018 – Transaction of ASME Turbo Expo 2017

This paper deals with a numerical study aimed at the validation of a computational procedure for the aerothermal characterization of preswirl systems employed in axial gas turbines. The numerical campaign focused on an experimental facility which models the flow field inside a direct-flow preswirl system. Steady and unsteady simulation techniques were adopted in conjunction with both a standard two-equation Reynolds-averaged Navier–Stokes (RANS)/unsteady RANS (URANS) modeling and more advanced approaches such as the scale-adaptive-simulation (SAS) principle, the stress-blended eddy simulation (SBES), and large eddy simulation (LES). Overall, the steady-state computational fluid dynamics (CFD) predictions are in reasonable good agreement with the experimental evidences even though they are not able to confidently mimic the experimental swirl and pressure behavior in some regions. Scale-resolved approaches improve the computations accuracy significantly especially in terms of static pressure distribution and heat transfer on the rotating disk. Although the use of direct turbulence modeling would in principle increase the insight in the physical phenomenon, from a design perspective, the trade-off between accuracy and computational costs is not always favorable.

https://gasturbinespower.asmedigitalcollection.asme.org/article.aspx?articleid=2665245

https://www.researchgate.net/publication/321452672_Numerical_Characterization_of_Flow_and_Heat_Transfer_in_Pre-Swirl_Systems

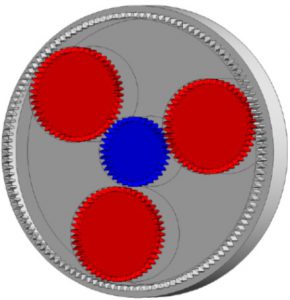

Computational Analysis of Windage Losses in an Epicyclic Gear Train

ASME Turbo Expo 2017 – GT2017-64917

Aside from increasing the overall engine pressure ratio, current trends in the design of innovative aircraft propulsion systems focus also on improving the propulsive efficiency. In this context, research efforts have been devoted towards the implementation of a new family of Ultra-High Bypass Ratio (up to 20) engines. In order to take into account the new constraints set by this innovative fan concept, configurations able to guarantee an independent optimization of the low pressure spool modules are more promising. This framework however introduces new challenges for the transmission system in terms of heat management and power losses, since the amount of power transferred through the gearbox is largely increased. Among the various types of losses occurring within the gearbox, whose relative magnitude largely vary depending on the operating conditions, one of the most significant at high rotational speeds is certainly windage.

This paper studies windage losses within an epicyclic gear train by means of CFD simulations. Superposition effect is assumed for the various losses contributions hence gear meshing is avoided to simplify the computational domain and separate the effects. Results obtained in this computational campaign highlight the influence of most relevant parameters such as oil concentration, chamber pressure and rotational speed. The response of the system to increased oil concentration and chamber pressure is linear with density variation, while power losses on both sun and planetary gears are shown to scale well with the third power of rotational speed. Furthermore the effects of geometrical modifications, introduced to avoid gear meshing, are studied and guidelines to scale the effective power losses is provided.

http://proceedings.asmedigitalcollection.asme.org/proceeding.aspx?articleid=2650169

https://www.researchgate.net/publication/319173114_Computational_Analysis_of_Windage_Losses_in_an_Epicyclic_Gear_Train

Numerical Characterization of Hot-Gas Ingestion Through Turbine Rim Seals

J. Eng. Gas Turbines Power 139(3) – Proceedings of ASME Turbo Expo 2016

This paper deals with a numerical study aimed at the characterization of hot-gas ingestion through turbine rim seals. The numerical campaign focused on an experimental facility which models ingress through the rim seal into the upstream wheel-space of an axial-turbine stage. Single-clearance arrangements were considered in the form of axial- and radial-seal gap configurations. With the radial-seal clearance configuration, computational fluid dynamics (CFD) steady-state solutions were able to predict the system sealing effectiveness over a wide range of coolant mass flow rates reasonably well. The greater insight of flow field provided by the computations illustrates the thermal buffering effect when ingress occurs: For a given sealing flow rate, the effectiveness on the rotor was significantly higher than that on the stator due to the axial flow of hot gases from stator to rotor caused by pumping effects. The predicted effectiveness on the rotor was compared with a theoretical model for the thermal buffering effect showing good agreement. When the axial-seal clearance arrangement is considered, the agreement between CFD and experiments worsens; the variation of sealing effectiveness with coolant flow rate calculated by means of the simulations displays a distinct kink. It was found that the “kink phenomenon” can be ascribed to an overestimation of the egress spoiling effects due to turbulence modeling limitations. Despite some weaknesses in the numerical predictions, the paper shows that CFD can be used to characterize the sealing performance of axial- and radial-clearance turbine rim seals.

http://gasturbinespower.asmedigitalcollection.asme.org/article.aspx?articleid=2547689

https://www.researchgate.net/publication/307439381_Numerical_Characterization_of_Hot-Gas_Ingestion_Through_Turbine_Rim_Seals