European Turbomachinery Conference 2015

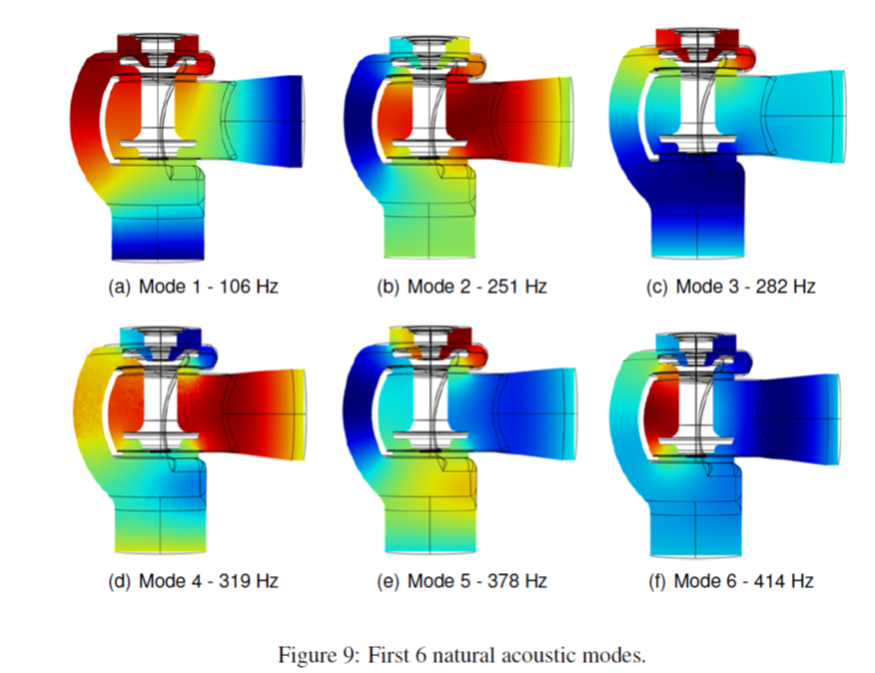

A computational analysis of the acoustic response of a double seat valve employed in the control stage of an industrial steam turbine was performed to verify possible criticalities in terms of mechanical stresses. Unsteady CFD was exploited to evaluate the unsteady pressure loads on selected positions. Turbulent flow simulations adopt the Scale Adaptive Simulation principle, as implemented in Ansys CFX 14.5 code, to partially resolve turbulence spectrum. 180 deg symmetric computational models were used, after verification that principal flow features of the full geometry were adequately reproduced, to maintain grid size below 20M cells. Purely acoustic computations exploiting the homogeneous Helmoltz equation were conducted first to identify natural acoustic modes and secondly to verify the forced response subjected to the unsteady pressure loads computed by CFD. Investigated frequency range is extended from 5 to 1000 Hz to comprehend all relevant structural modes. 4 different flow conditions were investigated to represent the entire operating range both in terms of characteristic Reynolds and Mach number. Obtained results shows that principal forcing frequency is characterized by a constant Strouhal number based on plug diameter and bulk flow velocity while main load amplitude is proportional to Reynolds number. Acoustic modes correspond to much higher frequencies so that the forced response does not generate critical stress levels on both valve stem and chest.