Journal of Engineering for Gas Turbines and Power 140(7) 2018 – Transaction of ASME Turbo Expo 2017

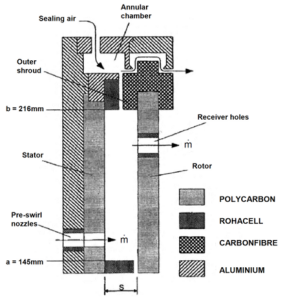

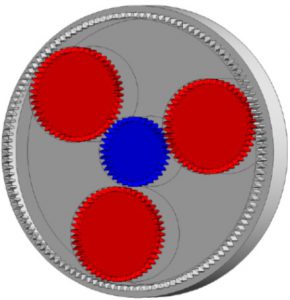

This paper deals with a numerical study aimed at the validation of a computational procedure for the aerothermal characterization of preswirl systems employed in axial gas turbines. The numerical campaign focused on an experimental facility which models the flow field inside a direct-flow preswirl system. Steady and unsteady simulation techniques were adopted in conjunction with both a standard two-equation Reynolds-averaged Navier–Stokes (RANS)/unsteady RANS (URANS) modeling and more advanced approaches such as the scale-adaptive-simulation (SAS) principle, the stress-blended eddy simulation (SBES), and large eddy simulation (LES). Overall, the steady-state computational fluid dynamics (CFD) predictions are in reasonable good agreement with the experimental evidences even though they are not able to confidently mimic the experimental swirl and pressure behavior in some regions. Scale-resolved approaches improve the computations accuracy significantly especially in terms of static pressure distribution and heat transfer on the rotating disk. Although the use of direct turbulence modeling would in principle increase the insight in the physical phenomenon, from a design perspective, the trade-off between accuracy and computational costs is not always favorable.

https://gasturbinespower.asmedigitalcollection.asme.org/article.aspx?articleid=2665245

https://www.researchgate.net/publication/321452672_Numerical_Characterization_of_Flow_and_Heat_Transfer_in_Pre-Swirl_Systems